JPE Industry Insights|The Hidden Risks and Solutions of Improper Installation

2025-09-02

Industry Knowledge Popularization

Improper (incorrect) installation is one of the most common hidden sources of risk in instrumentation and fluid piping systems. If not detected and corrected early, it can lead to leakage, stress corrosion, maintenance difficulties, and a significant increase in downtime costs. This article outlines common types, causes, risks, and a set of immediately executable inspection and improvement recommendations to help engineers and construction teams implement effective prevention during design and field installation.

What is “Improper Installation”?

What are the common types ?

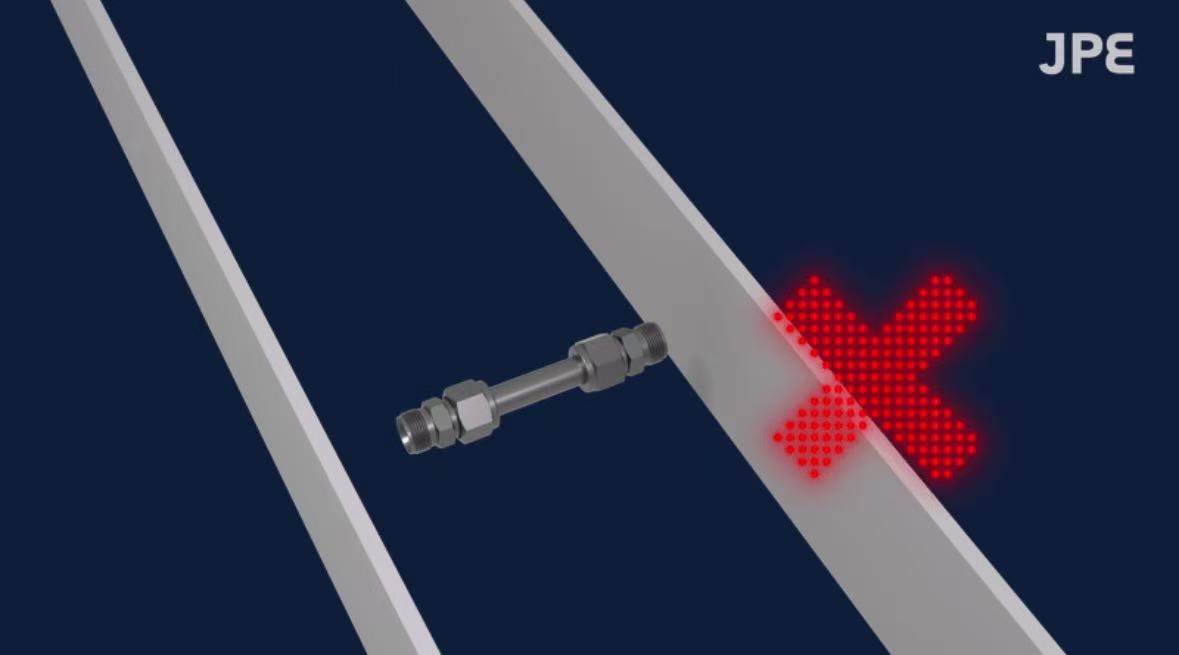

Common Mistake 1. Piping without proper support

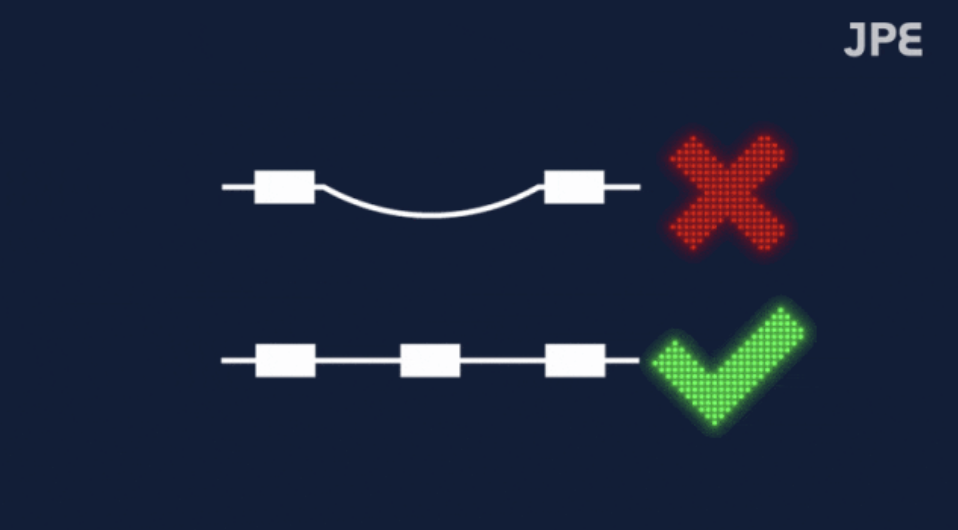

a. When piping sags due to excessive length or heavy weight caused by high-density media, it should be properly supported.

b. Piping usually carries the weight of shut-off valves, pressure-reducing valves, filters, and other components, all of which should be adequately supported.

If left unsupported, all the weight and resulting stress will fall on the tube fittings. When the load becomes excessive, leakage risk is inevitable and should be avoided.

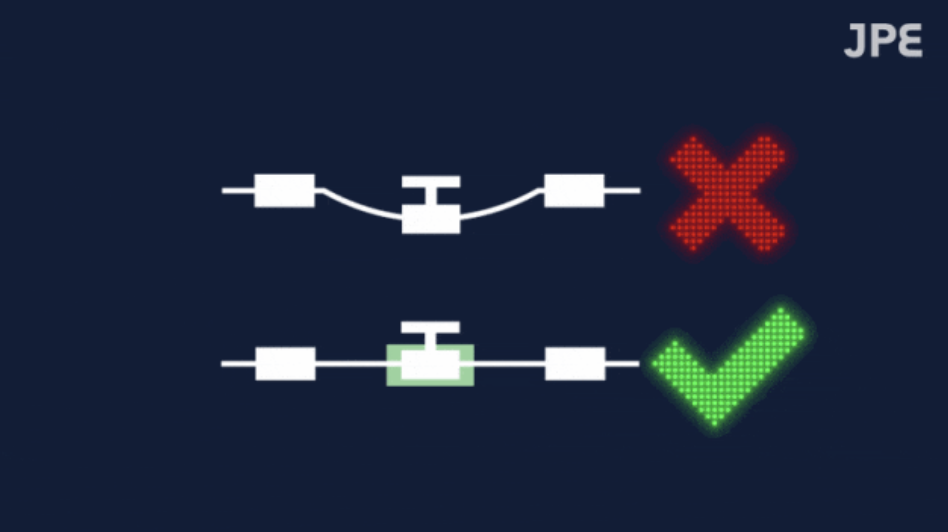

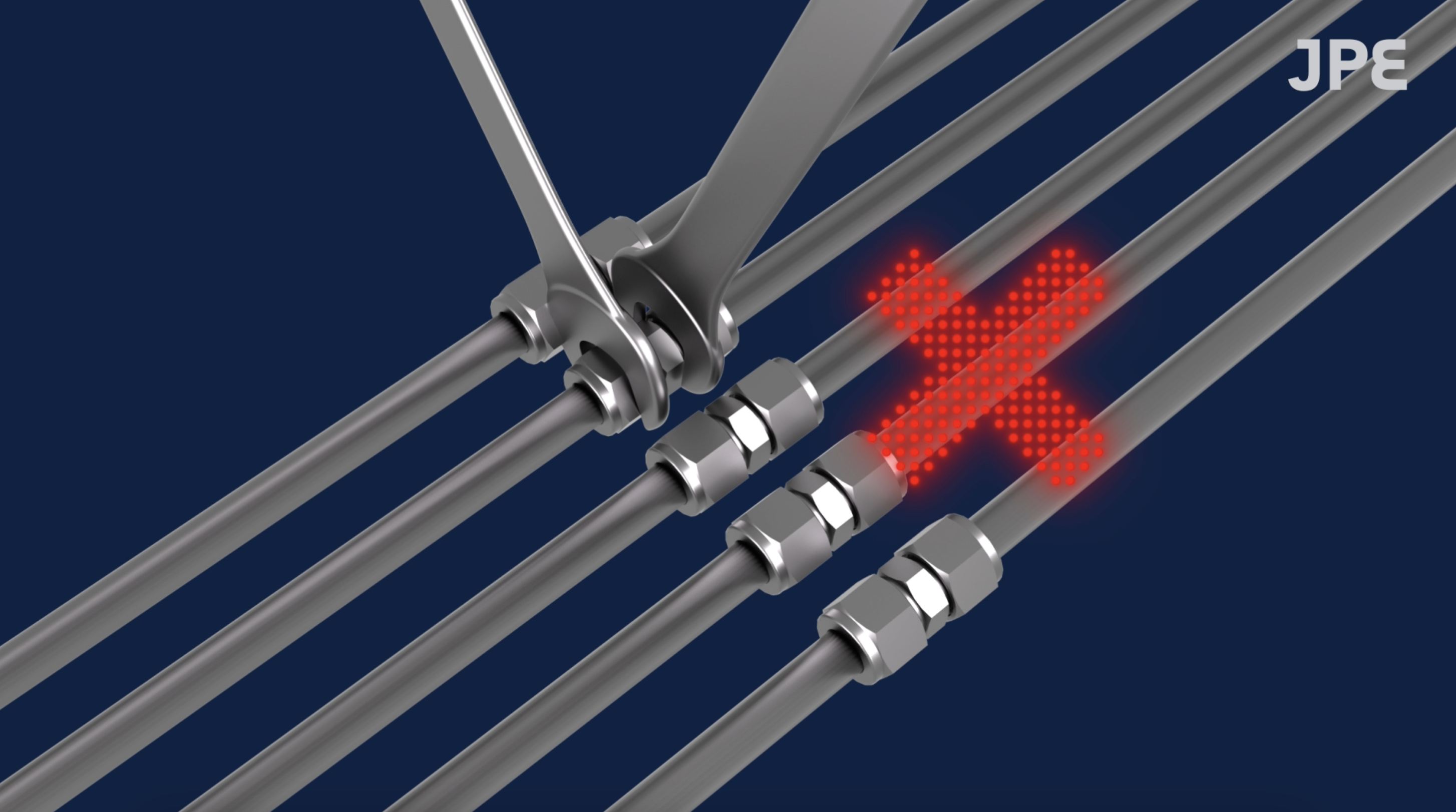

Common Mistake 2. Lack of proper installation and maintenance space

a. When laying multiple pipe routes, initial installation may be straightforward as lines are installed in sequence. However, future maintenance may be extremely difficult due to limited operation space, leading to higher maintenance costs or even unserviceable situations.

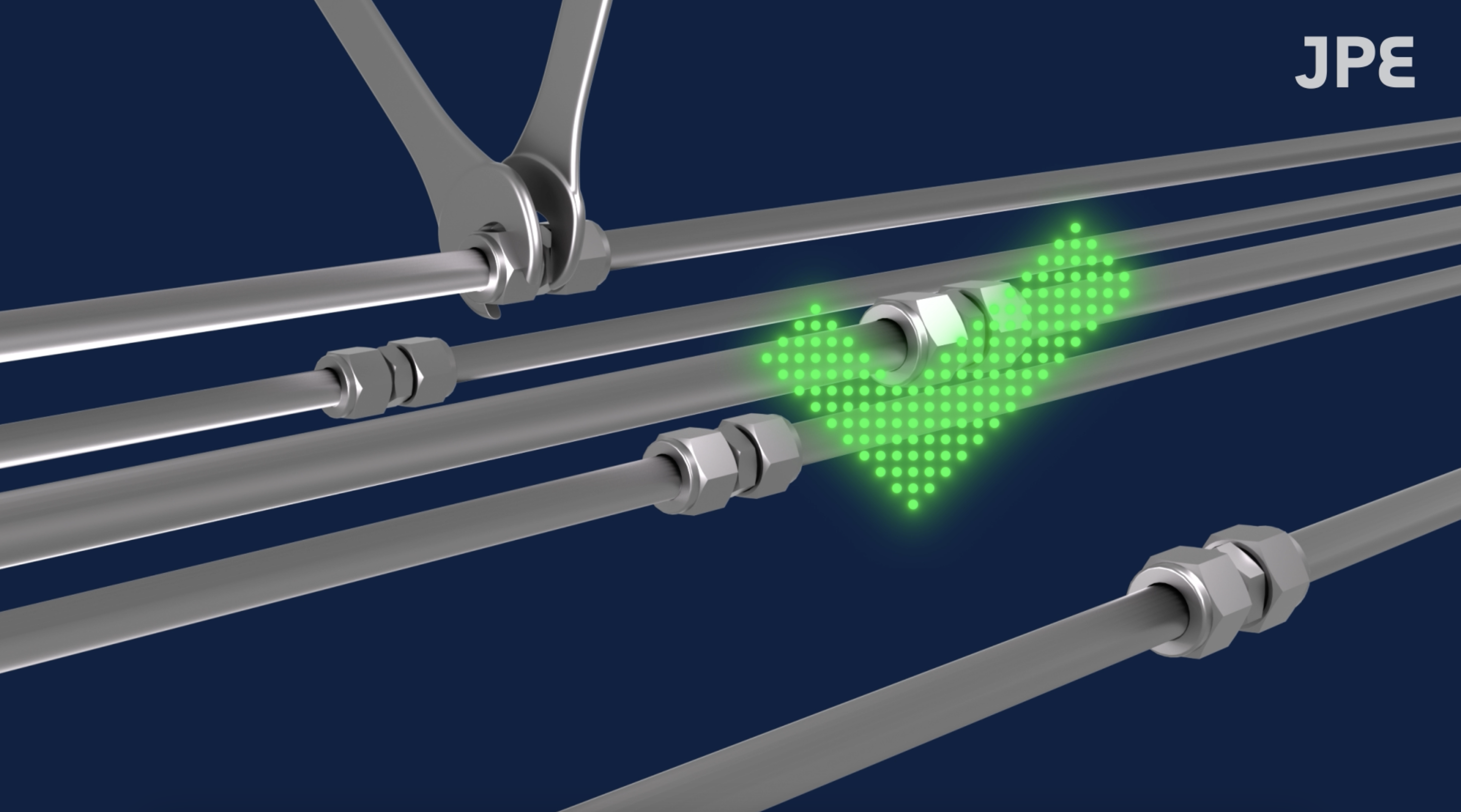

Therefore, fitting positions should be staggered and sufficient wrench space should be provided. This facilitates installation, saves space, and ensures a maintenance-friendly design for future servicing.

b. A straight pipe section between two fixed fittings is completely unmaintainable and must be avoided.

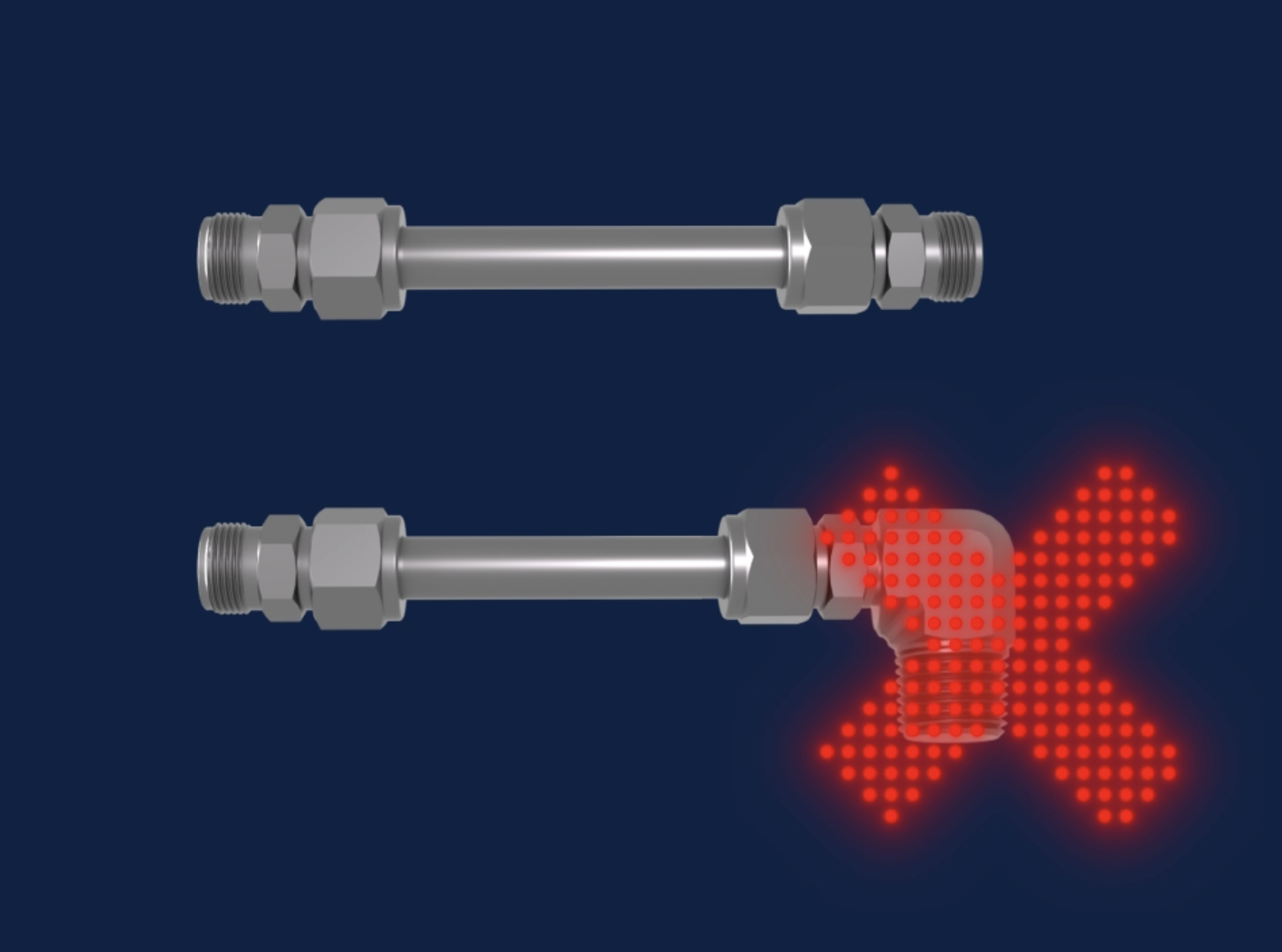

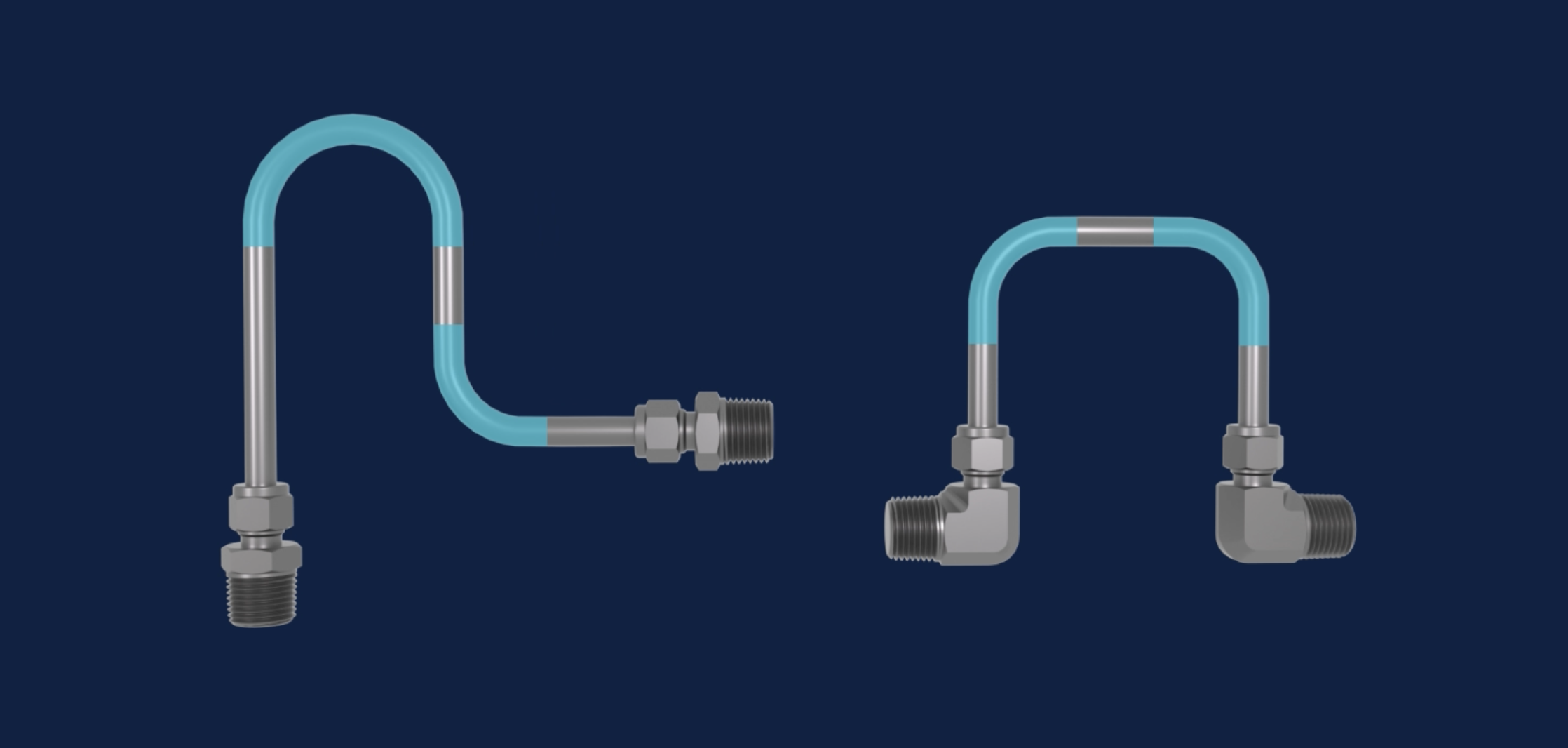

Common Mistake 3. No expansion loop design

A straight pipe between two fixed fittings, when forced against both fitting ends, creates significant conflict.

a. During installation, as the fitting nut is rotated for a certain number of turns, it inevitably drives the tube forward, creating large tensile stress on both ends of the straight pipe.

b. Both ambient temperature and fluid-induced temperature cause thermal expansion of the pipe. Once this occurs, large unavoidable stress is generated on the piping.

These stresses, caused by the absence of an expansion loop, directly result in leakage. Furthermore, this type of installation cannot fully seat the pipe against both fitting ends even with precision CNC cutting, violating standard installation procedures.

**【Incorrect Installation】**

In the above cases, leakage is inevitable. Thermal expansion will cause pipe movement and generate large stress, while the pipe cannot be properly seated against both fitting ends, violating standard installation procedures.

**【Correct Installation】**

The above cases allow sufficient space for thermal expansion, simplify installation and disassembly, and ensure the pipe is correctly inserted into both fitting ends, in compliance with standard installation procedures.

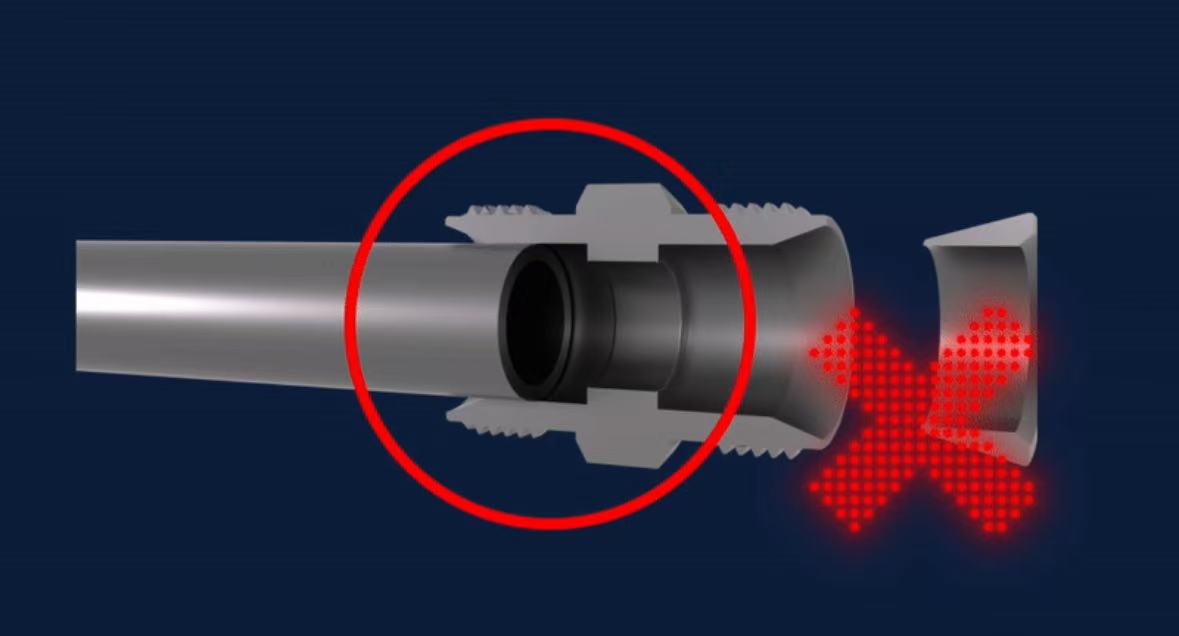

Common Mistake 4. Inaccurate manual cutting and bending of tubes

Insufficient accuracy in manual cutting and bending is very common in practice. Due to time constraints and environmental pressure on site, installers often resort to forcing, pushing, pulling, or jamming the tube into the fitting without proper adjustment. This leads to two major problems:

a. Piping under great stress places extreme leakage risk on the fittings and hides the danger of stress corrosion.

b. In such installation, the pipe cannot properly seat against the fitting bottom, violating standard installation procedures.

Therefore, engineers with proper professional training should carefully design and measure pipe length and angles, and make patient adjustments during bending to eliminate stress before inserting the pipe into the fitting, thereby avoiding leakage risks.

It must be managed across the entire chain—from design, procurement, construction, to maintenance—to systematically avoid foreseeable issues and reduce leakage and premature failure risks. Recommendations include:

1. Incorporate requirements for support, expansion loops, and maintenance space clearly during the design drawing stage.

2. Include inspection checklists in acceptance criteria (including pressure testing and seating verification).

3. Provide installation and inspection training for on-site personnel, and establish routine inspection checklists and abnormality reporting mechanisms.

A reliable and experienced partner not only provides assurance of quality for critical components but can also offer precise and reasonable selection advice at the early stage of pipeline planning. This contributes to rational overall layout and system safety, making them an excellent source of consultation.